Trivia of Plastic

10

04

2024

A Brief Discussion on Common Plastic Materials and Plastic Extrusion

Common Plastic Materials and Their Characteristics

-

Polyethylene (PE): Known for its lightweight and toughness, this material is widely used in manufacturing plastic bags and bottles. Its low-density variant (LDPE) is suitable for films and linings, while the high-density version (HDPE) is commonly used for making sturdy containers and pipes.

-

Polypropylene (PP): Frequently found in microwave-safe food containers and automotive components due to its high-temperature resistance. PP’s chemical resistance also makes it an ideal material for chemical storage tanks.

-

Polyvinyl Chloride (PVC): Available in rigid and flexible forms, rigid PVC is often used in the construction industry for pipes and window frames, while flexible PVC is used for electrical insulation or medical tubing. The robust characteristics of rigid PVC make it suitable for applications requiring high durability, such as motorcycle inner cable sheaths, providing protection and preventing wear.

-

Polystyrene (PS): Commonly used in packaging materials, especially in the food industry, transparent PS plastic boxes and disposable utensils are its typical applications.

-

Polycarbonate (PC): Renowned for its high transparency and impact resistance, commonly used to make eyeglasses, bulletproof glass, and CDs. PC is not acrylic; compared to PMMA (a common acrylic material), PC offers higher impact resistance and temperature tolerance.

-

Polyethylene Terephthalate (PET): The primary material for beverage bottles and food containers, providing sturdy and recyclable packaging solutions.

Applications of Plastic Extrusion Technology

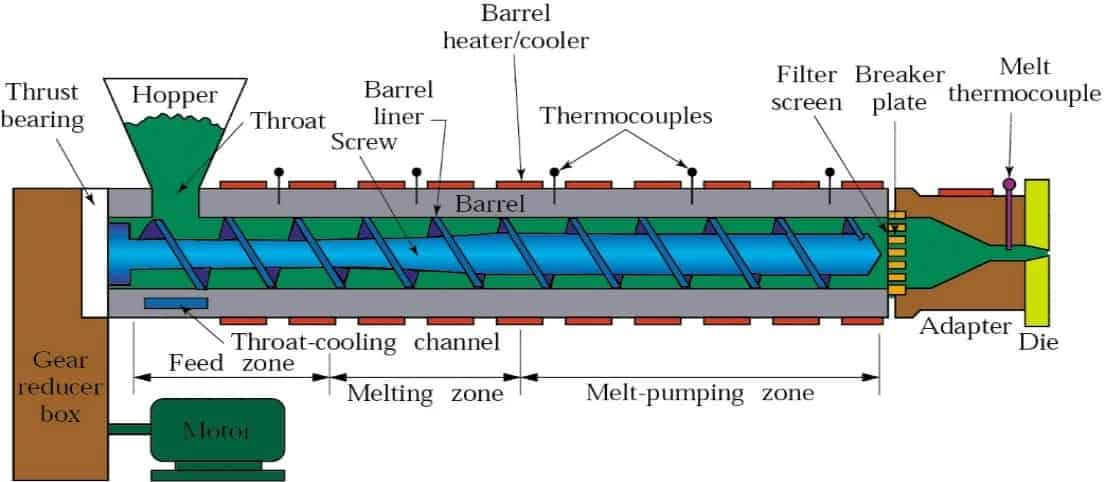

Extrusion is a process where plastic materials are heated to a pliable state and then shaped through a die to form long products of various shapes. This technology's flexibility makes it an ideal choice for producing customized plastic products:

-

Tubes and cable sheaths: Require precise size and shape control, widely used in the electricity and communication industries.

-

Stationery: Such as folder edges and pen casings, available in various colors and durable materials.

-

Outdoor furniture: Such as plastic tables and chairs, produced using extrusion technology to withstand weather conditions and offer various colors.

-

Decorative trims: Used in automobiles and homes, needing to combine aesthetics and durability.

Through plastic extrusion technology, companies can create products that meet specific functional and aesthetic requirements.

In Taiwan, companies specializing in this field, such as WEITRAI, offer diverse solutions to meet the market's demand for high-quality plastic products.

Image Source: By SAURABH RANJAN

Image Source Description: The images used in this article are sourced from the internet, intended only for educational and informational purposes. If the copyright owner of any images does not wish them to appear here, please contact us, and we will remove them promptly.

|

Disclaimer: We strive to ensure the accuracy and timeliness of the content. However, all information should be considered as a basic reference and not a substitute for professional advice. We welcome and encourage readers to discuss the content further with us, whether by consulting our expert team or engaging in-depth discussions with industry peers. If you have any questions or would like to provide feedback on related topics, please contact us. We can explore these complex topics more thoroughly and jointly advance the industry. |